- By YACHT Solutions

Aluminum Boats and Bottom Paint

Aluminum hulls and conventional toxic paints containing heavy metals don’t work well together:

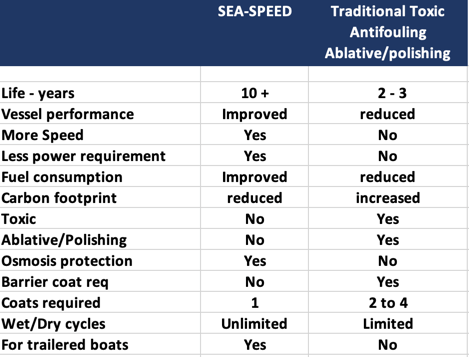

Multiple coats of epoxy barrier paints must be used to shield the Aluminum hulls from the Copper containing conventional antifouling paint to prevent electrolysis. Epoxy is generally quite heavy and adds substantial weight to the boat thereby reducing performance.

The Answer is SEA-SPEED V 10 X ULTRA. A novel coating system was developed and tested over 7 years. Extensively used by the toughest customers on the Planet, US Navy Seal teams. Performance, Durability, and a long TEN (10) year Lifecycle.

SEA-SPEED is a silane – Siloxane hull coating that does not contain heavy metals such as Copper (Cuprous oxide) or Zinc nor any chemical biocides. Remove the worry of electrolysis. It is also non-permeable against water and gases preventing oxidation and maintaining a clean look. The coating is also ideal for boats that go in/out of the water or on trailers. The effectivity of the coating is not changed by wet/dry cycles.

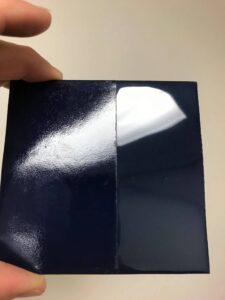

Smooth and Slick Anti-Fouling Bottom Paint

A very smooth, less than one-micron surface roughness improves performance requiring less power and fuel or higher top speeds. An easy clean surface can be maintained by using the boat or a quick wipe down periodically.

A spray-on or roll-on application direct to blasted aluminum or over an epoxy barrier. SEA-SPEED V 10 X ULTRA is available in CLEAR, ULTRA White, or USN Black. CLEAR can be applied over our 8 different color epoxy barrier coat SEAPOXY 73. Disc sanded hulls will require an epoxy barrier.

At $2.10 per square foot initial cost for material it is exceptionally cost – effective protection lasting ten years.

SHARE THIS:

Related Posts

Using a Yacht For Business